Equipo de trituración

Equipo de molienda

Dolomite is widely distributed with hardness within 3.5-4 and specific gravity within 2.85-2.9. It is a kind of carbonate minerals and includes ferrodolomite and kutnahorite. The greywhite dolomite looks like limestone. Commonly, the calcite content in dolomite is lower than 5%. Dolomite can be used in such fields as construction material, ceramics, glass, fireproofing material, chemistry, agriculture, environment protection and energy conservation, etc.

| Fineness | Applications | Recommended Equipment |

| Below 200meshes | Used to produce putty powder and additives of fodders( Calcium content is above 55.6 and no harmful ingredient exists.) | MTM,MTW |

| 250-300meshes | Used as raw materials of plastic, rubber, coating, waterproof material plants and wall coatings(whiteness is above 85.) | MTW,MTM |

| 350-400meshes | Used to produce pinch plate, water pipe and chemical products (whiteness is above 93). | SCM |

| 400-600meshes | Used to produce toothpaste and soap (whiteness is above 94). | SCM,LUM |

| Above 800meshes | Used to produce rubber, plastic, cable and PVC (whiteness is above 94). | SCM,LUM |

| Above 1250meshes | Used as raw materials of PVC,PE, paint, coating, bottom & surface coating of papermaking and ink, etc. | SCM,LUM |

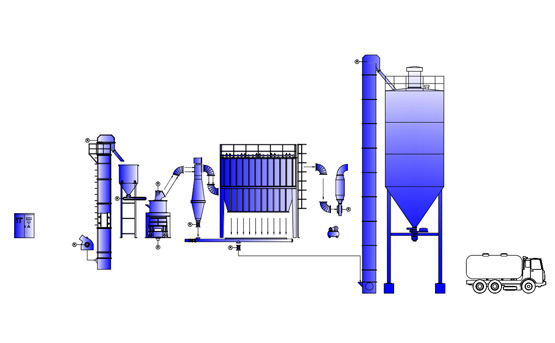

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.