Equipo de trituración

Equipo de molienda

Barite is the most common mineral of barium. Its component is barium sulfate. Its Moh's hardness is 3-3.5 and specific gravity is 4.0-4.6. Barite can be used as white pigment (commonly known as lithopone). Besides, it can be used in such industries like chemical engineering, papermaking, textile, filler and glass production where it can be cosolvent and add the lightness of glass. Of them, about 80-90% of barite is used as the heavy agent of drilling mud in oil drilling process.

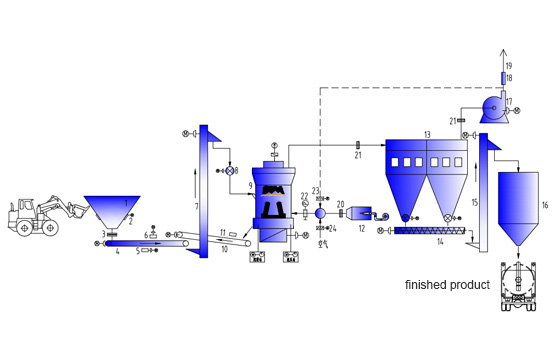

1.Crushing Stage:After homogenization in bedding plant, big blocks of barite would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to intermediate bunker by conveyor.