Equipo de trituración

Equipo de molienda

Petroleum Coke is got after crude oil separates, through distillation, light oil from heavy oil which then undergoes fission. It is the terminal “waste” in petroleum refining process. In terms of shapes, it can be divided into 4 kinds--- needle coke, spherical coke, sponge coke and powdery coke. So far, petroleum coke hasn't been listed as national energy and recorded in the energy consumption indices. Replacing oil by petroleum coke as fuel is a good way in new energy application and meets national policies.

| Raw Material | Fineness | Application | Recommended Equipment |

| Needle Coke | Around 200meshes | The needle coke has low resistance and thermal expansivity, so its powder can be used in anode production and carbon factory. | MTM,MTW |

| Spherical Coke | Around 200meshes | Used as the combustion materials of ceramic and glass factory. When petroleum coke powder as combustion materials replaces heavy oil, the profits we can get: Taking the current price as standard—petroleum coke powder costs 2300 yuan per ton and heavy oil 4800 yuan per ton, the same quantity of heat given by heavy oil per ton needs petroleum coke about 1.2 tons in terms of their heat value. Taking 5 tons of heavy oil as daily furnace consumption, (we can save 10200 yuan per day). | MTM,MTW |

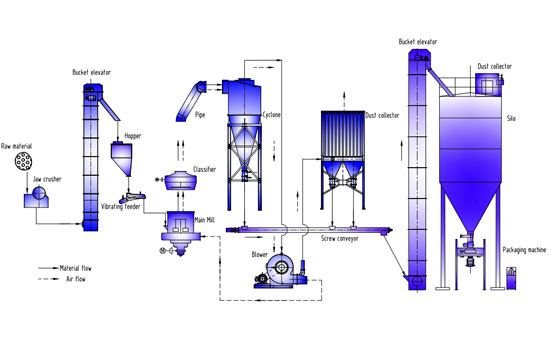

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.