Equipo de trituración

Equipo de molienda

The widely distributed calcite is also known as stalactite with the hardness within 2.7-3.0 and specific gravity within 2.6-2.8. Calcium carbonate is the main component so it can be used to produce heavy and light calcium powder. Calcite with different fineness is widely used in papermaking, medicine, chemistry and agriculture. Heavy calcium is closely related to people's lives. In the past decade, globally, the annual production capacity of heavy calcium increased by 5%-8% on average, while that of China 10%. Calcium carbonate powder processing is still an emerging industry.

| Fineness | Applications | Recommended Equipment |

| Below 325meshes | 325meshes of calcite is commonly used to produce putty powder. It can also be raw materials in chemistry and cement industry. For metallurgy, calcite can be solvent; for construction, materials to produce cement and lime; for food, the additives. Besides, the filling of calcite can make glass semitransparent so it can be used in lampshade production. | MTW |

| 400-800meshes | Used to produce high-quality putty powder, plastic, paper, toothpaste and soap, etc.. | SCM,LUM |

| Above 800meshes | Used to produce rubber, plastic, cable and PVC (whiteness above 94) | SCM,LUM |

| Above1250meshes | Can be raw materials of PVC, PE, paint, coating, bottom &surface coating of papermaking and ink, etc.. | SCM,LUM |

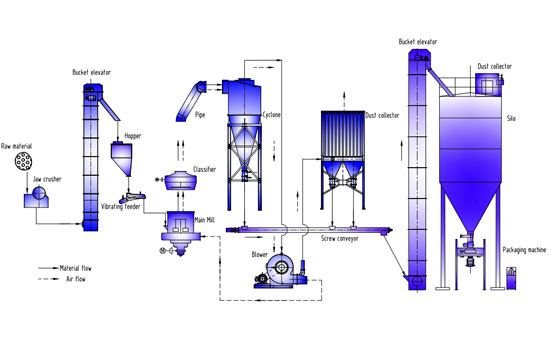

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.